- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Stofring mpmdhs -serie

MPMDHS -series van stofring zijn speciale rubberen afdichtingsringen die worden gebruikt in hydraulische cilinders, voertuigen, mechanische apparatuur en bouwmachines om de inbraak van stof en vuil te voorkomen.

Stuur onderzoek

Stofafdichtingen worden over het algemeen gebruikt in combinatie met ronde rubberen ringen in sommige mechanische apparatuur en hydraulische zuigersystemen. Ze zijn geïnstalleerd in de verbindingsonderdelen van de machines om te voorkomen dat extern stof en vuil de apparatuur invoeren. Vooral in grote graafmachines en bulldozers die in harde omgevingen werken, zijn een groot aantal stofafdichtingen vereist in het vierwielgebied en het hydraulische systeem om te voorkomen dat modder en zand indringing worden en de machines beschermen.

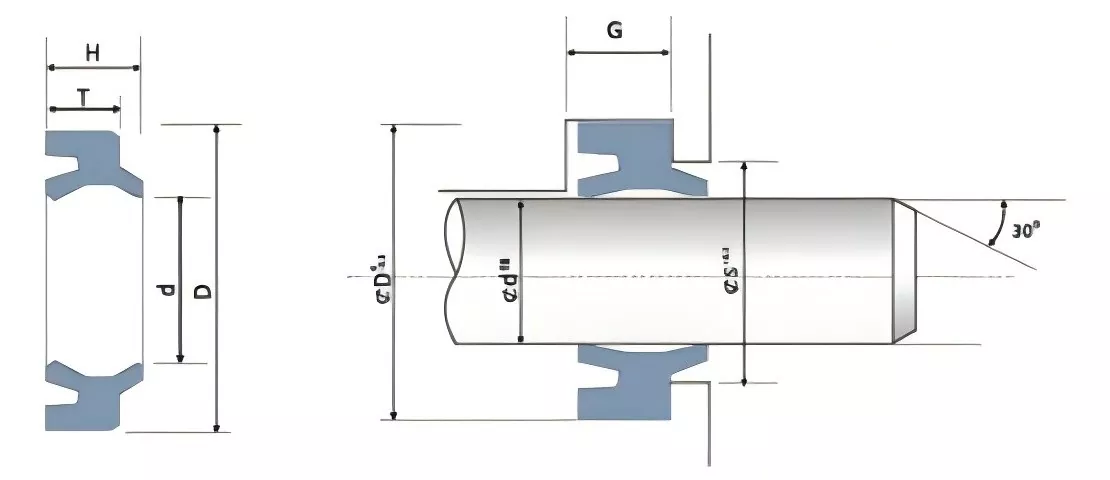

Productparameters:

Groove oppervlakte -kenmerken

|

Finish |

Rtmax (één) |

VK (um) |

|

Slidingsurface |

≤2.5 |

0,1-0,5 |

|

Grofebottom |

≤6.3 |

≤1,6 |

|

Grooveside |

≤15 |

≤3 |

|

Model |

Groove maat |

||||||

|

Ref. Nee |

φd |

φd |

φs |

T |

H |

G |

B |

|

DHS0011B |

11.2 |

19.2 |

15.5 |

4.5 |

6.0 |

5 |

2 |

|

DHS00012 |

12 |

20 |

16.3 |

4.5 |

6.0 |

5 |

2 |

|

DHS0012E |

12.5 |

20.5 |

16.8 |

4.5 |

6.0 |

5 |

2 |

|

DHS00014 |

14 |

22 |

18.3 |

4.5 |

6.0 |

5 |

2 |

|

DHS00016 |

16 |

24 |

20.3 |

4.5 |

6.0 |

5 |

2 |

|

DHS00018 |

18 |

26 |

22.3 |

4.5 |

6.0 |

5 |

2 |

|

Dhos00020 |

20 |

28 |

24.3 |

4.5 |

6.0 |

5 |

2 |

|

DHS00022 |

22 |

30 |

26.3 |

4.5 |

6.0 |

5 |

2 |

|

DHS00022D |

22.4 |

30.4 |

26.7 |

4.5 |

6.0 |

5 |

2 |

|

DHS00023E |

23.5 |

31.5 |

27.8 |

4.5 |

6.0 |

5 |

2 |

|

DHS00025 |

25 |

33 |

29.3 |

4.5 |

6.0 |

5 |

2 |

|

DHS00028 |

28 |

36 |

32.3 |

4.5 |

6.0 |

5 |

2 |

|

Dhos00030 |

30 |

38 |

34 |

5 |

6.5 |

6 |

2 |

|

Dhos00031e |

31.5 |

39.5 |

35.5 |

5 |

6.5 |

6 |

2 |

|

DHS00032 |

32 |

40 |

36 |

5 |

6.5 |

6 |

2 |

|

Dhos00035 |

35 |

43 |

39 |

5 |

6.5 |

6 |

2 |

|

DHS00035S |

35.5 |

43.5 |

39.5 |

5 |

6.5 |

6 |

2 |

|

Dhos00036 |

36 |

44 |

40 |

5 |

6.5 |

6 |

2 |

|

DHS00038 |

38 |

46 |

42 |

5 |

6.5 |

6 |

2 |

|

Dhos00040 |

40 |

48 |

44 |

5 |

6.5 |

6 |

2 |

|

Dhos00045 |

45 |

53 |

49 |

5 |

6.5 |

6 |

2 |

|

DHS00050 |

50 |

58 |

54 |

5 |

6.5 |

6 |

2 |

|

DHS00053 |

53 |

61 |

57 |

5 |

6.5 |

6 |

2 |

|

DHS00055 |

55 |

63 |

59 |

5 |

6.5 |

6 |

2 |

|

DHS00056 |

56 |

64 |

60 |

5 |

6.5 |

6 |

2 |

|

Dhos00060 |

60 |

68 |

64 |

5 |

6.5 |

6 |

2 |

|

Dhos00063 |

63 |

71 |

67 |

5 |

6.5 |

6 |

2 |

|

Dhos00065 |

65 |

73 |

69 |

5 |

6.5 |

6 |

2 |

|

DHS00067 |

67 |

75 |

70 |

5 |

6.5 |

6 |

2 |

|

DHS00070 |

70 |

80 |

75 |

6 |

8.0 |

7 |

3 |

|

DHS00071 |

71 |

81 |

76 |

6 |

8.0 |

7 |

3 |

|

Dhos00075 |

75 |

85 |

80 |

6 |

8.0 |

7 |

3 |

|

DHS00080 |

80 |

90 |

85 |

6 |

8.0 |

7 |

3 |

|

DHS00085 |

85 |

95 |

90 |

6 |

8.0 |

7 |

3 |

|

DHS00090 |

90 |

100 |

95 |

6 |

8.0 |

7 |

3 |

|

Dhos00095 |

95 |

105 |

100 |

6 |

8.0 |

7 |

3 |

|

DHS00098 |

98 |

108 |

103 |

6 |

8.0 |

7 |

3 |

|

DHS00100 |

100 |

110 |

105 |

6 |

8.0 |

7 |

3 |

|

DHS00105 |

105 |

115 |

110 |

6 |

8.0 |

7 |

3 |

|

DHS00110 |

110 |

120 |

115 |

6 |

8.0 |

7 |

3 |

|

DHS00112 |

112 |

122 |

117 |

6 |

8.0 |

7 |

4 |

|

DHS00115 |

115 |

125 |

120 |

6 |

8.0 |

7 |

4 |

|

DHS00120 |

120 |

130 |

125 |

6 |

8.0 |

7 |

4 |

|

DHS10120 |

120 |

133 |

127 |

7 |

9.5 |

8 |

4 |

|

DHS00125 |

125 |

138 |

132 |

7 |

9.5 |

8 |

4 |

|

DHS00130 |

130 |

143 |

137 |

7 |

9.5 |

8 |

4 |

|

DHS00136 |

136 |

149 |

143 |

7 |

9.5 |

8 |

4 |

|

DHS00140 |

140 |

153 |

147 |

7 |

9.5 |

8 |

4 |

|

DHS00145 |

145 |

158 |

152 |

7 |

9.5 |

8 |

4 |

|

DHS00150 |

150 |

164 |

158 |

7 |

9.5 |

8 |

4 |

|

DHS00160 |

160 |

174 |

168 |

7 |

9.5 |

8 |

4 |

|

DHS00165 |

165 |

179 |

173 |

7 |

9.5 |

8 |

4 |

|

DHS00170 |

170 |

184 |

178 |

7 |

9.5 |

8 |

4 |

|

DHS00180 |

180 |

193 |

187 |

7 |

9.5 |

8 |

4 |

|

DHS10180 |

180 |

194 |

188 |

7 |

9.5 |

8 |

4 |

|

DHS00185 |

185 |

198 |

192 |

7 |

9.5 |

8 |

5 |

|

DHS00190 |

190 |

203 |

197 |

7 |

9.5 |

8 |

5 |

|

DHS00200 |

200 |

213 |

207 |

7 |

9.5 |

8 |

5 |

|

DHS00200 |

200 |

214 |

208 |

7 |

9.5 |

8 |

5 |

|

DHS00204 |

204 |

248 |

212 |

7 |

9.5 |

8 |

5 |

|

DHS00210 |

210 |

223 |

217 |

7 |

9.5 |

8 |

5 |

|

DHS00220 |

220 |

233 |

227 |

7 |

9.5 |

8 |

5 |

|

DHS00230 |

230 |

244 |

238 |

7 |

9.5 |

8 |

5 |

|

DHS00250 |

250 |

263 |

257 |

7 |

9.5 |

8 |

5 |

Krijg nu een offerte

▶ Kenmerken

MPMDHS-type is een afdichting met oliebestendige lip en stofbestendige lip.

▶ Materiaal

Polyurethaan pu

▶ Medium

Hydraulische olie, water, emulsie.

▶ Werkomstandigheden

Werksnelheid: ≤1m/s

Werktemperatuur: -35 ℃ ~+100 ℃